You're odd - I know because I checked

11 comments

Don't be offended by my title; I don't mean you! I don't think you're odd at all probably but...Maybe I do; you'll never know I guess. I'm going to draw a line in the sand and simply say we're all a little odd, because...Well, we are! But let's talk about bullets.

I've been reloading over the last few days; that means making my own ammunition. I've been focusing on handgun calibres and over the last week have produced four thousand 9mm rounds. I'm loathe to the allow my stock of ammunition to dip below a certain minimum-level and because I've been practicing for an upcoming three-gun event I've been sending a lot of rounds down range.

I don't mind the job, in fact I find it relaxing. I throw on some music and spend hours in my workshop performing the repetitive task. There's snacks too of course. Always.

What I do mind however is faulty ammunition which is why I check and recheck each item after manufacture. It's a quality-assurance process that is a little tedious but essential to safety and good performance.

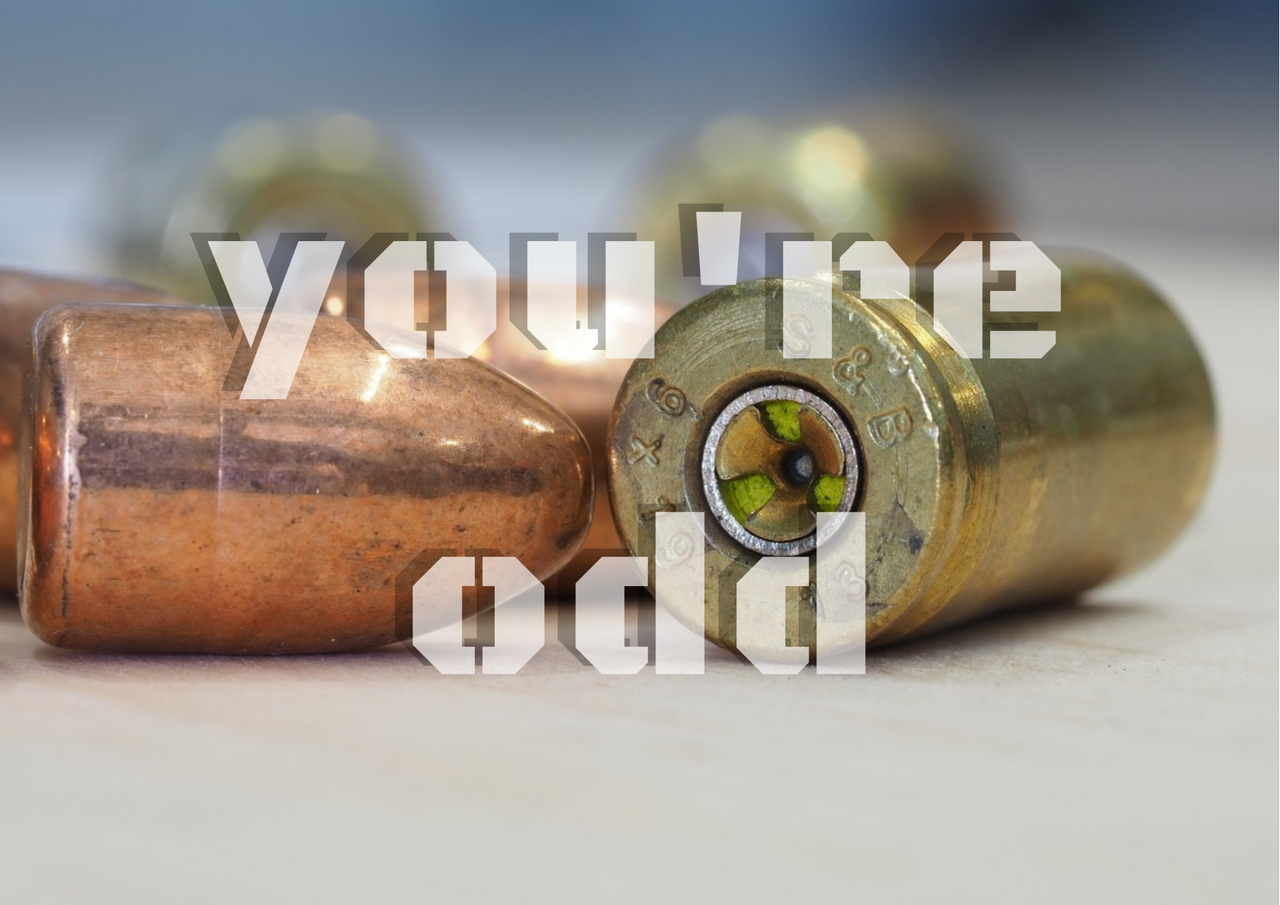

Above is a faulty 9mm round. You can see the primer is inverted. That yellow coloured stuff is the charge that is supposed to explode into the case to ignite the accelerant when the hammer is dropped on the primer. Clearly this one won't work.

Quality assurance

Mass-producing my handgun rounds means there's room for error.

With the rifle rounds I make, precision rounds, I have the luxury of checking each one individually, in fact each stage of their manufacture is checked and rechecked; with rifle rounds it can take hours to make just one hundred. But with the handgun ammunition I make the process is a little more automated and I can make around five hundred or more in a single hour. It's about volume although I still want a high level of quality.

The handgun rounds fall into a tub as I work, around one per second or so, and then the checking process begins. It's a basic visual inspection primarily to ensure the primer is seated the right way around, and mostly they are, although every now and then one goes in the wrong way. The secondary check is for split cases and projectiles seated upside down which occurs sometimes. I check for split cases in the cleaning process prior to the rounds being made but considering I pick up each one to verify the primer I double check the rounds.

Further to that quality check I do a second inspection for any rounds I plan to take into competition; it's called a drop test. This involves breaking down the handgun they will be used in, taking the barrel and dropping each individual round into it to make sure it goes in and out of the chamber easily; tedious for sure, but I'm a diligent fellow.

Why I verify the rounds

When I shoot handguns I'm running and gunning and sending lots of rounds down range.

In a competition an individual stage could require sending thirty to forty rounds in a fifteen to twenty second period with running and reloading in between; the discipline, IPSC, simulates military and law enforcement situations. In the middle of a stage where one is firing rapidly having a malfunction due to faulty ammunition is bad - It causes one to slow down and lose time and of course can be dangerous also.

If a round is too tight in the chamber, through the case having not being resized properly in the reloading process properly, it may not eject efficiently when fired causing a jam and again the loss of precious time. With scores being a combination of time and accuracy shooting in less time is preferable. Sometimes an oversized case may prevent the slide closing up also, which means the handgun won't fire the subsequent round. A problem.

This image shows my bullet puller - A simple but effective tool that uses kinetic energy to remove the bullet from the case and contains the accelerant that also falls out.

Here's how the round is retained in the puller, using that silver collet. Once the cap is screwed onto the puller the operator hits the end of it [a hard hammer blow] on a hard surface; I use the concrete floor. With the puller stopping so suddenly but the bullet being free to continue that forward motion it pops out of the case. [The puller stops, the bullet keeps moving forward - Physics y'all.]

After drop testing my competition rounds I mark them up as such and pack them away for use later. I generally keep two thousand competition-verified rounds on hand at all times and replenish up to that level when required.

With any I find that have inverted primers I isolate them and when I've got several, which could be a year or more, I use the kinetic bullet puller to disassemble them; eventually they get reassembled down the track so nothing is wasted, including the primer and powder [accelerant].

Getting bitten

Firearms are dangerous, there's no question about it; when put in the hands of a human that is. In, and of itself, a firearm is completely harmless - Unlike humans. Having said that, firearms bite sometimes and it's not always the operators fault, just mostly. I've seen people do some dumb things and get away with it but also others do dumb things and get bitten. It's never pleasant, mostly bloody and painful.

So many things can go wrong with firearms and when it happens injury or death can occur; Lost fingers, hands, eyes, faces, holes in oneself or someone else...It can and does happen which is why I'm careful, why I practice a lot and why I deploy a solid quality assurance process when I make ammunition and with my firearms in general. Faulty components and equipment is not something I tolerate.

I check and verify my rounds and equipment because I have a safety-first ethos; blowing my hand off or getting a handgun slide or rifle bolt through my head would ruin my day, and life too. From there it comes down to my ingrained need to perform, to be the best version of myself. I don't see the point in competing without 'striving to perform at my best' and that means the shooting, physical fitness, strategy and the preparation of my equipment and ammunition.

Over the last week or so I've found a few odd rounds; one had the primer in the wrong way and the other two the primer wasn't seated flush in the primer pocket. So, three odd rounds out of four thousand 9mm rounds...I'd say that's not too bad, a 0.075% defect rate is acceptable to me. The important thing is I checked though, eliminated the odd ones.

Anyway, that's about it I guess. Feel free to ask any questions, call me odd or indeed explain to me what makes you odd in the comments below. 😁

Design and create your ideal life, don't live it by default - Tomorrow isn't promised so be humble and kind

Discord: galenkp#9209

Images are mine.

Comments